If you’ve decided to upgrade your cycling tyres to tubeless ones, you may be wondering if there’s a difference between the rims of tubeless and tube-tyres. You may have heard that they are safer, but is there really a difference? Keep reading to learn more about the benefits of tubeless tyres.

Compared to tube-tyres

Compared to tube type tyres, tubeless tyres are significantly lighter. The lack of tube means that when the carcass punctures, air loss is gradual. Because the tyre carcass does not have to be replaced, punctures can be repaired easily with a tyre plaster, vulcanisation, or a puncture repair strip. As with tube type tyres, however, it is important to consider your driving style.

Compared to tubeless tyre, a tube-free bike has fewer punctures than a road-cycling bicycle with a tube-filled tyre. Flats can be caused by small pieces of glass or staples that poke through a tube. In harsh desert environments, thorns can also puncture a tube-less tyre. Tubeless tyres are also heavier, which makes them more difficult to mount. Pro road-racing cyclists have begun slowly transitioning to tubeless bicycle tyres.

Another benefit of tubeless tyres is their ability to reduce tyre weight. Tube-type tyres require that the tyre never leak air. A tube-type tyre’s sealant will repair a small hole. A tubeless tyre will also run at a lower pressure than its tube-type counterpart. A tubeless tyre will not lose any air during a puncture.

In addition to lower resistance while driving, tubeless tyres are easier to repair and last longer than tubes. In addition, tubeless tyres are easier to maintain than tube-type tyres, and can be repaired more quickly. Tube-type tyres are also more fragile and require extra energy to operate, affecting their gas mileage. They also improve a car’s handling characteristics by being a lot lighter.

When compared to tubeless tyres, tube type tyres are lighter, and tend to leak less air than tubeless tyres. This is because a tube tyre’s casing does not rub against its casing. This frequent contact between tyre and casing can cause a tube to rupture and cause a crash. The result can be catastrophic.

While tubeless tyres do cost more than tubed tyres, the price difference isn’t too great. Both types have their advantages. Tubeless tires are easier to repair and perform better on the road, but tubed tyres are a better option for heavy-duty vehicles and spoke-rimmed motorcycles. If you are buying tubeless tyres for your car, consider their benefits and disadvantages.

They have no inner tube

The difference between a tubeless tyre and a tube-tyre is that a true tubeless tyre has no inner or outer hose, meaning the air is held directly in the tyre’s rim. A tube-type tyre has an inflatable inner tube, which holds air in the tyre’s sidewall. Tubeless tyres tend to be lighter than a tube-tyre, and this helps with fuel efficiency. They also require less weight in their balance, making them ideal for vehicles with alloy or normal wheels.

While a tubeless tyre does work with a tube-type rim, it can be difficult to mount and dismount. This can cause a lot of problems when mounting a tube. While a tubeless tyre will operate without an inner tube, the sealant will be extremely sticky and will make installing an inner tube difficult.

A tubeless tyre is also more difficult to maintain than a tube-tyre. The sealant in the tubeless rim can dry out and leak if a puncture occurs. It is recommended that you top up your sealant once or twice a year, depending on how much you ride and how often you ride. Adding sealant can also help prevent a pinch flat, which is a situation where the tyre hits an obstacle and deforms, creating a double puncture. Tubeless tyres also allow for lower pressures, which means better traction.

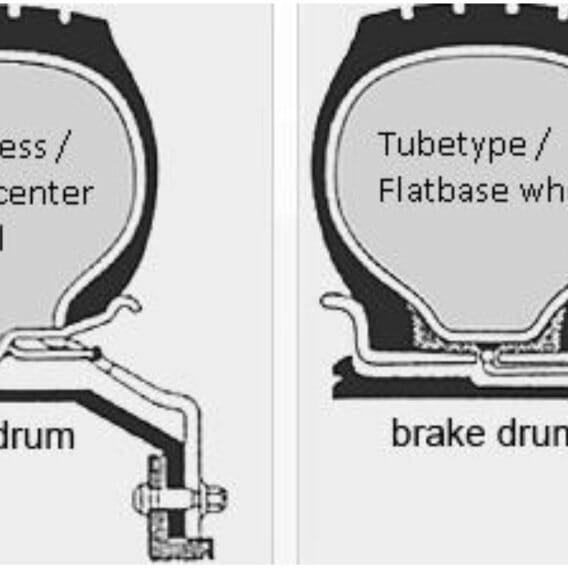

Another key difference between a tubeless tyre and a tube-tyre is the type of rim. A tubeless tyre can be used on rims with inner tubes or two-piece rims. Tubeless tyres are generally lighter and less bulky than tube-tyres. However, they do require the installation of tubeless sealant.

Both types of tyres use a similar general cross-section as a clincher, but without the inner tube. In both cases, the casing is sealed with a liquid sealant. The beads in a tubeless tyre are square, unlike those in a clincher. This means a tighter seal, but it also means that it is more difficult to secure the rim of a tube-tyre.

They are safer

As the name suggests, tubeless tyres are airtight. The casing of tubeless tyres holds the weight of the vehicle, while the tube of a conventional tyre holds the air. The benefits of tubeless tyres are many. The absence of a tube means that the tire stays cooler and doesn’t suffer from the problems of conventional tyres. They are also easier to balance, with less uneven weight in the tire.

The primary difference between tubeless and tube-tyre tires is rim design. Tubeless tyres use a wider rim than tube-tyres, which increases their overall efficiency and speed. However, they are more difficult to repair, since the rim is not airtight. If you have problems with your tubeless tyre, you will need to replace the entire rim to avoid causing any further damage to the rim.

When a tube punctures, the air trapped inside the rim is able to escape. This causes a rapid deflation. In the event of a puncture, the driver can quickly lose control of their vehicle. The risk of accidents is greater if the puncture happens while riding at high speeds. If you have a tube puncture, it’s important to seek immediate professional help, as the air will escape through the rim.

Although tubeless tyres have lower air pressure, they do not lose air pressure as quickly as tube-tyres. A puncture in a tubeless tyre does not cause immediate deflation. Therefore, you will have a much lower risk of having a flat, as the air will remain in the tyre itself.

The tubeless tyres are more fuel efficient, which helps reduce gas consumption. Because of their light weight and reduced rolling resistance, tubeless tyres reduce fuel consumption. This is another reason why they are more environmentally friendly. It also reduces engine workload, making them safer to drive. The benefits of a tubeless tyre include reduced maintenance costs and increased mileage.

They have different rims

A tubeless tyre is similar to a tube-type tyre, except that it doesn’t have an inner-tube. Instead, the wheel rim and tyre form an air container, with a valve permanently attached to the rim. Tubeless tyres are less susceptible to deflating because the rim of the tyre acts as a sealant. Because of this, tubeless tyres don’t lose air very quickly, but can potentially burst if the driver makes a mistake.

In both cases, the rim of the wheel forms an air-tight seal. The inner tube must fit snugly inside the tire‘s carcass, so that it doesn’t fold prematurely. An incorrect-sized tube can also overstretch and cause an overheated tyre. Additionally, a poorly-fitting tube can leak air, causing the tyre to burst.

Another difference between tubeless and tube-type tyres is that the former produces less heat. Tubed tyres produce less heat as the air flows directly into the rim. In addition, a tubeless tyre produces less friction, meaning it produces less heat. This is also beneficial for fuel economy, as a tubeless tyre is lighter and requires less gas to maintain traction.

Generally, tubeless tyres are safer for driving as they don’t lose air suddenly when a puncture occurs. In addition, tubeless tyres are easier to repair, and can be used for a longer period of time after they’ve been inflated. Compared to tube-tyres, tubeless tyres can run a higher mileage without deflating, which is a big advantage for those who drive frequently.

Tubeless tyres are more expensive than tube-tyres, but they do offer a better ride and increased traction. For more information on tubeless tyres, read on. They’re also more lightweight due to the lack of casing. So, how do you tell which one is better for your riding?

There’s a difference between tubeless and tube-tyre valve stems. Tubeless tyre valve stems come with a knurled nut and rubber grommet that seals the valve hole on the rim. The nut and rubber grommet profile are specific to the cross-section of the rim. A valve stem made for one wheel company won’t work on a different brand of rim.